The Acid Test: How Agricrete's Protective Systems Stand Up to Muriatic Acid

Discover the remarkable durability of Agricrete's PIM+ Type S and PTS+ treatments when subjected to 25 rounds of muriatic acid exposure.

Darell Chamberlain

Darell Chamberlain The Acid Test: How Agricrete’s Protective Systems Stand Up to Muriatic Acid

Ever wonder just how durable a paving stone can be when confronted with harsh chemicals? We put our PIM+ Type S and PTS+ protective treatments to the ultimate challenge—muriatic acid. Here’s a behind-the-scenes look at our simple yet rigorous test and the dramatic results after 25 rounds of repeated acid exposure.

Step 1: Preparing the Samples

We started by removing the top half-inch from three identical paving stones. One stone was left completely untreated to serve as our control. The other two were treated with PIM+ Type S.

Step 2: Layering the Protection

After allowing the PIM+ Type S to cure for at least three days on both treated stones, we added a second layer of defense—PTS+—but only on one of them. This set the stage for a clear comparison:

- Untreated Stone

- Stone with Only PIM+ Type S

- Stone with PIM+ Type S + PTS+

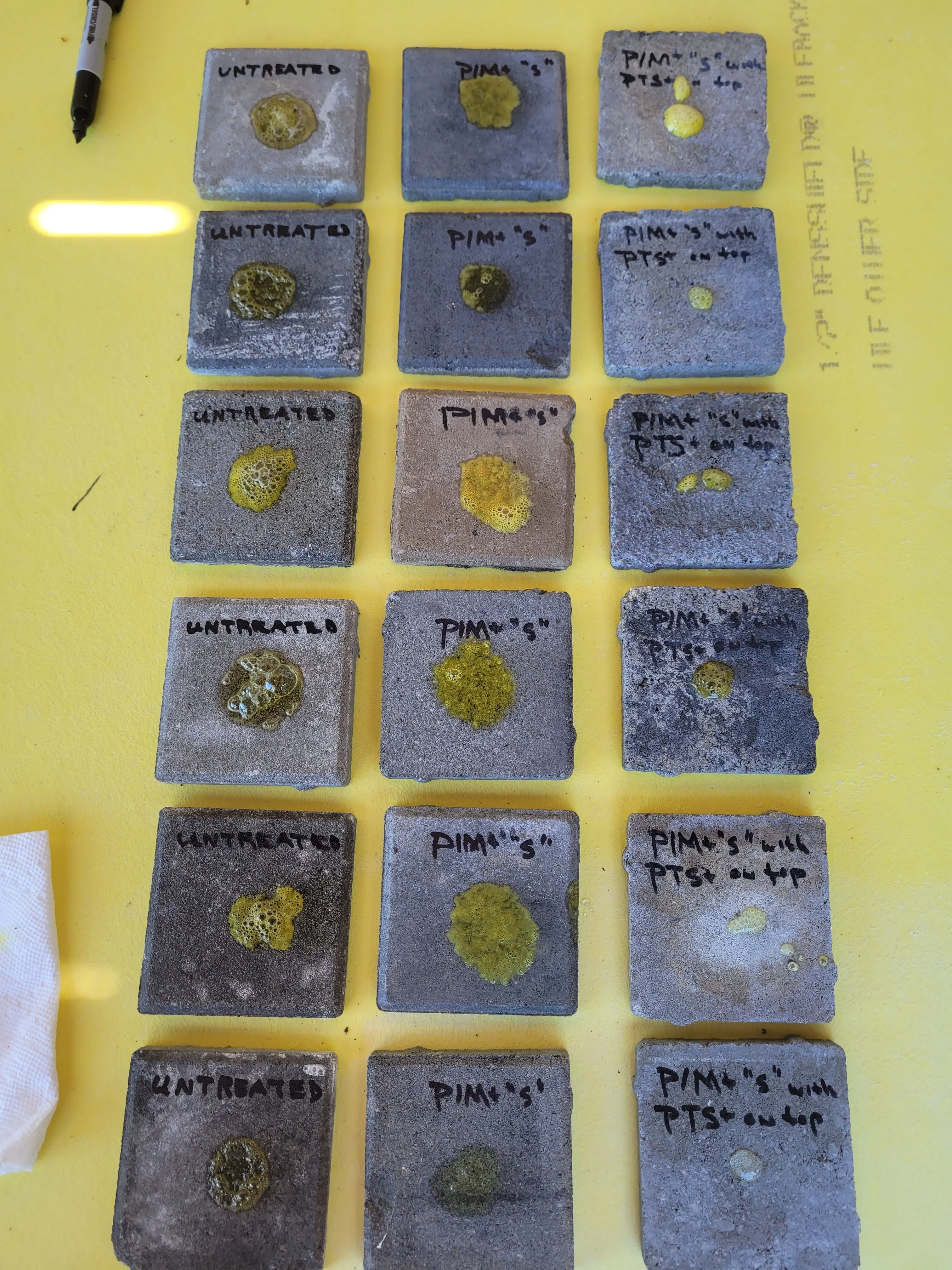

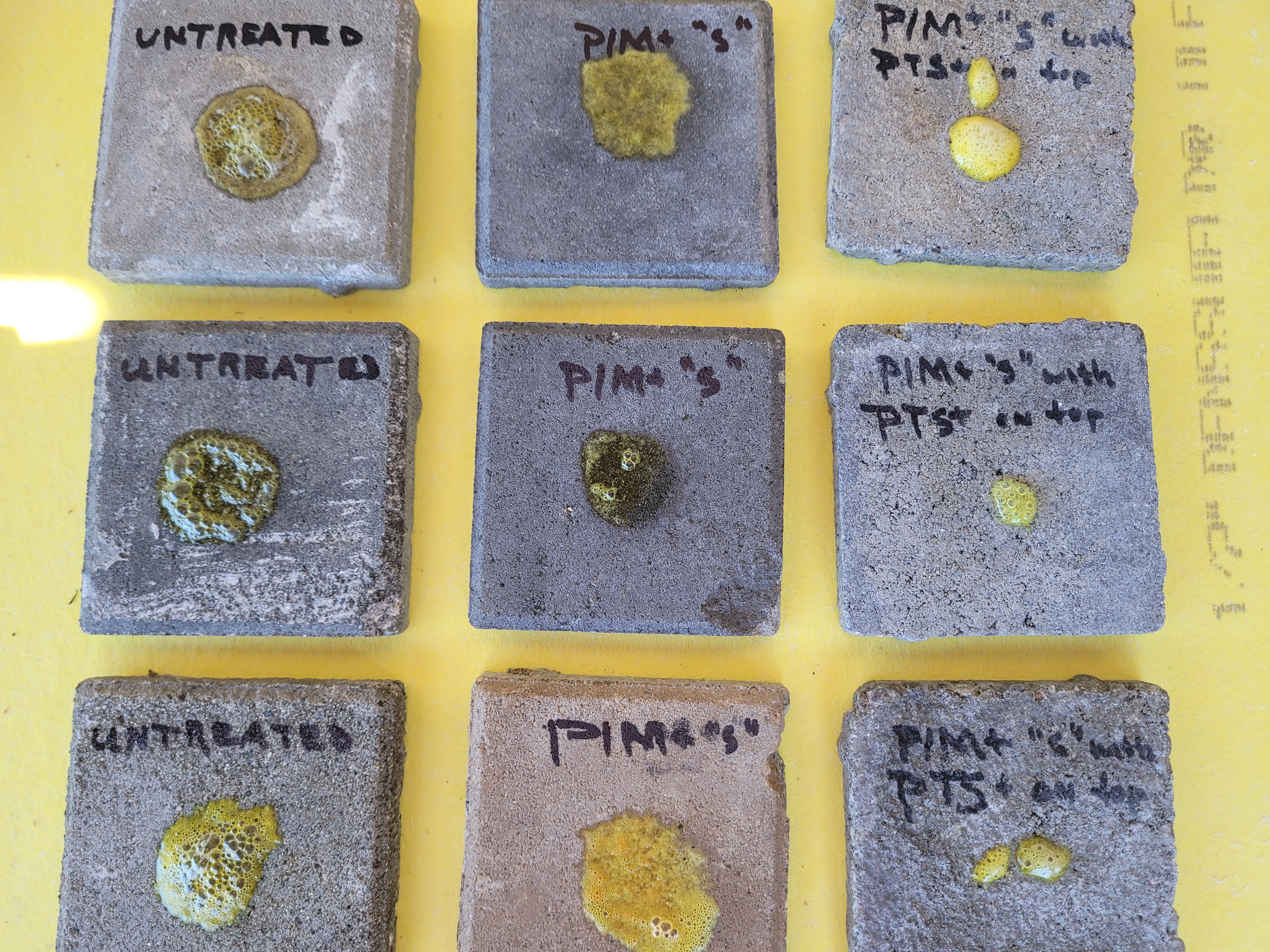

Step 3: The Initial Acid Test

Using an eyedropper, we carefully placed three drops of muriatic acid on each stone and observed:

- Untreated Stone: The acid bubbled furiously, penetrating and reacting instantly with the surface.

- PIM+ Type S–Treated Stone: There was mild bubbling, but the acid couldn’t easily penetrate; instead, it spread out across the surface.

- PTS+ Over PIM+ Type S: The acid formed a bead on top, showing virtually no reaction.

Step 4: 25 Rounds of Reapplication

We didn’t stop there. After two minutes, we blotted off the acid and reapplied it—doing this a total of 25 times. While the untreated stone continued to degrade, the double-layered stone (PIM+ + PTS+) showed no visible reaction even after repeated exposure.

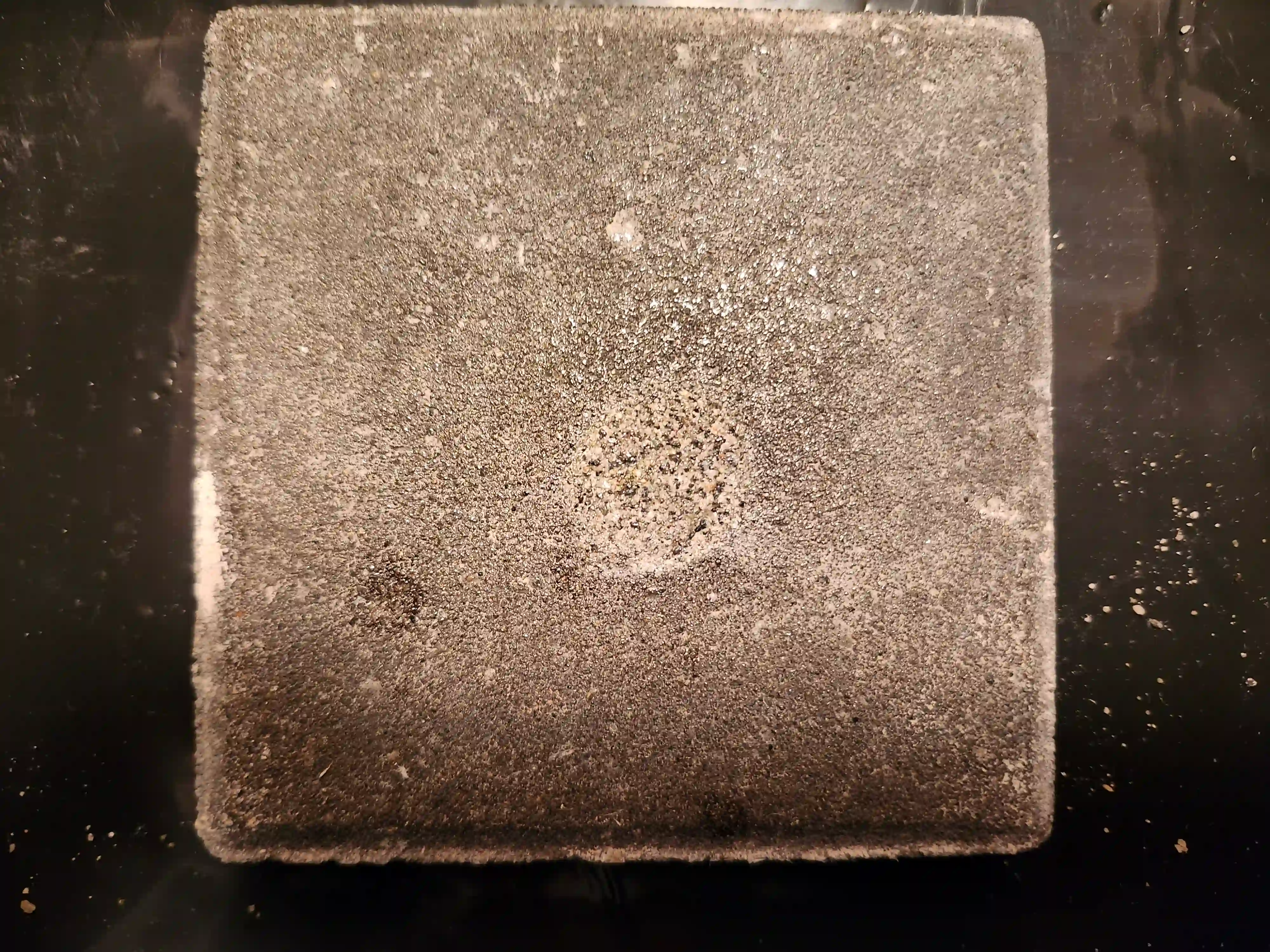

Step 5: The Final Results

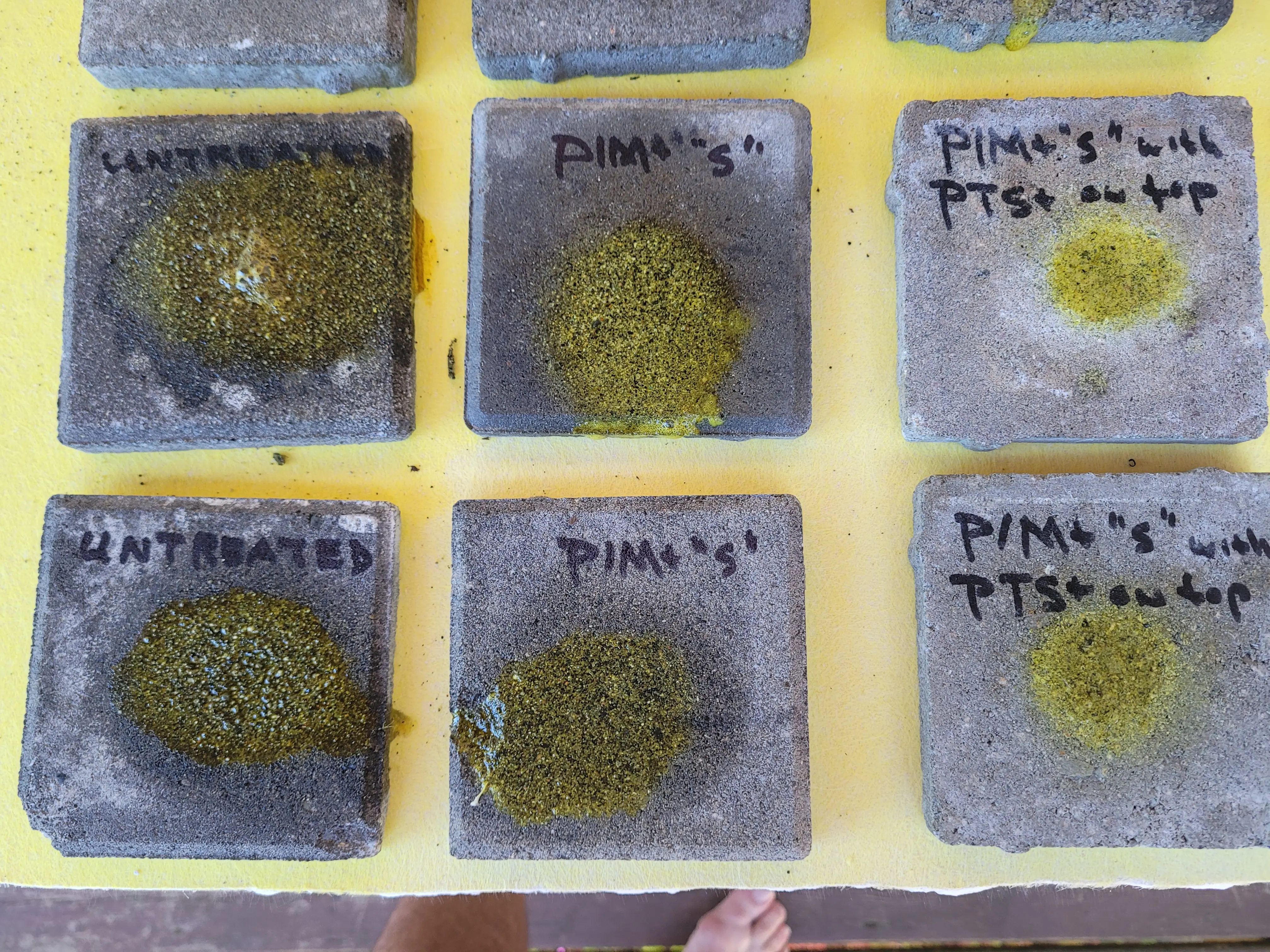

After these 25 rounds, the difference in damage was striking:

-

Untreated Stone: Developed a hole about 1/8 of an inch deep packed with black sand.

-

PIM+ Type S–Treated Stone: No hole, but there was a larger black spot on the surface. Rubbing a finger across it revealed a bit of black sand.

-

PTS+ Over PIM+ Type S: Zero damage. Only a slight discoloration occurred, not from the acid itself but due to the repeated blotting process.

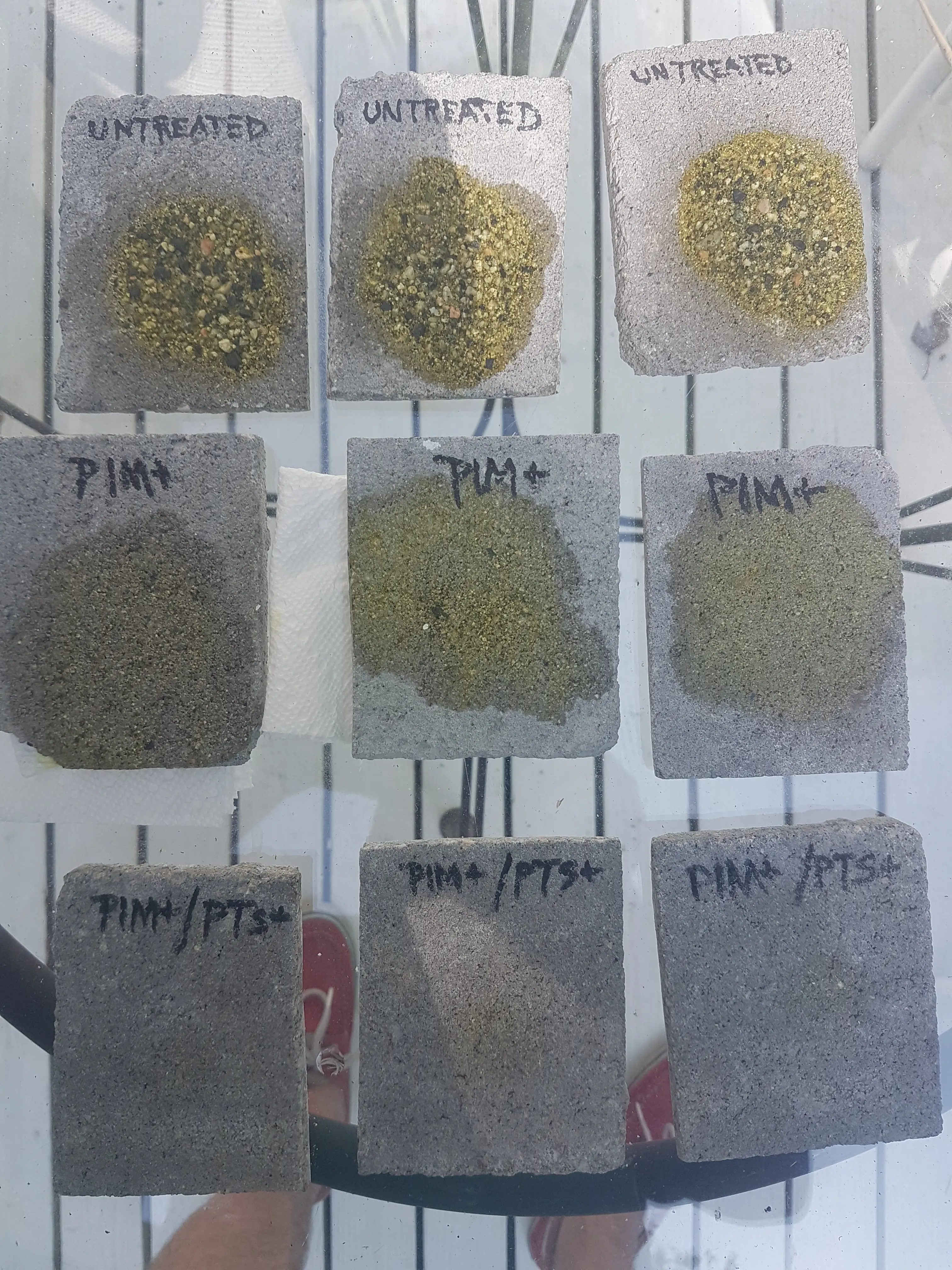

Side-by-Side Comparison

Here’s how all three samples looked after the complete 25-round acid test:

Final Takeaways

Our test confirms that Agricrete’s multi-layer approach—using PIM+ Type S followed by a coating of PTS+—offers superior protection against strong acids. Whether you’re safeguarding concrete floors in a commercial kitchen or outdoor surfaces prone to chemical spills, this combination provides unmatched durability and peace of mind.

Learn more about our revolutionary 2-Product Concrete Preservation System and how it can provide comprehensive protection for your concrete surfaces.

Interested in learning more about how our products can extend the life of your concrete and paving surfaces? Contact Agricrete or explore our website for additional details and pricing. Because when it comes to harsh chemicals, why take chances when you can take control?